He’s advocated phosphorus recovery for two decades and it's finally here!

Christian Kabbe, CEO of EasyMining Germany, has spent more than two decades working to realise a vision for sustainable phosphorus recovery. With the first Ash2Phos plant now approved to be built in Schkopau, Germany, he sees both a major step forward and an industry-leading model for the region.

05 Dec 2024For Kabbe, bringing phosphorus recovery to the market stage has been a career-long goal. Back in the 1980s, when the first environmental protection movement was underway in Europe, he studied chemistry with an ambition of tackling chemical pollutants. From there, he helped develop Germany’s first strategy for phosphorus recovery in the late 2000s before continuing into EU-level projects that would form a European community around the nutrient.

His mantra through it all? “Think forward, act circular!” And now that the world’s first Ash2Phos plant is becoming a reality, phosphorus recovery has entered an exciting new phase: truly circular solutions are within reach.

– The circular economy is no longer just an option but a must for economic and societal survival. And once we have our first Ash2Phos plant up and running, it will accelerate the rollout of phosphorus recovery dramatically, says Kabbe.

A first-of-its-kind facility for nutrient recovery

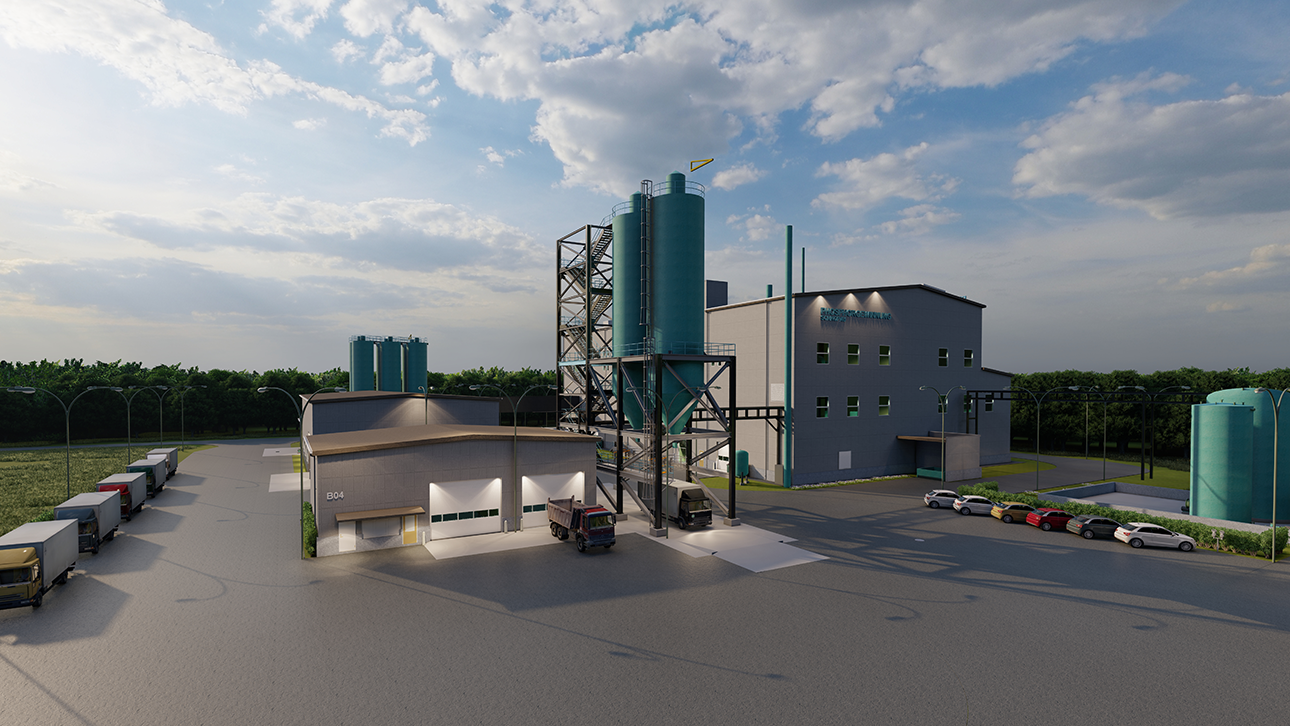

The plant, currently under construction in Schkopau, Germany, will house a large-scale implementation of EasyMining’s Ash2Phos technology.

That process recovers more than 90% of the phosphorus from incinerated sewage sludge. The result is a renewable high-grade phosphate ready for direct use as fertiliser and as one of the most versatile raw materials in any phosphate value chain, replacing mined phosphate rock in linear models and thus making them circular.

Kabbe highlights the important role EasyMining has played in developing new processes for nutrient recovery. The key with innovations like Ash2Phos has been their emphasis on producing high-quality materials, something Kabbe considers essential for the shift to circularity.

– EasyMining has always focused on having a process that is as simple and robust as possible, yielding market-grade materials, because recovery only makes sense if the recovered material has a market uptake, he says.

3D print of the Ash2Phos plant in Schkopau, Germany, set to begin operation in 2027.

Leading the way for circularity in Europe

Kabbe has worked with nutrient recovery long enough to experience both the excitement of technological breakthroughs and the frustration of slow policy development. In Europe, regulatory changes have not matched the pace of innovation, a pattern that continues to hinder the shift to circularity.

One challenge has been how some EU regulations focus on the origin of nutrients rather than their quality. For example, phosphorus recovered from sewage sludge is banned from being used as feed phosphates even if the quality is of a higher grade than those from mined phosphate rock. There’s a long–overdue paradigm shift of quality over origin that would holistically enable the circular economy.

According to Kabbe, another factor is simply some policymakers’ reluctance to enact mandates for circularity. Germany, Switzerland, and now Austria have established regulations with mandatory deadlines for phosphorus recovery. However, while other countries around Central Europe have expressed interest in a similar approach, they have been hesitant to pass legislation.

– There’s a lot of discussion around whether all these processes and technologies really work and can be applied everywhere. The first plant is always the hardest one. But once you have a good working example out there, it makes things a lot easier by giving others something to replicate, he explains.

Tirelessly advocating for a shared vision

As construction begins in Schkopau, Kabbe will continue advocating and building new coalitions for the circular transition. Through the Clean Phosphorus 2029 Initiative (Initiative Sauberer Phosphor 2029), he works with stakeholders across Germany to promote a shared vision for sustainable phosphorus recovery.

That initiative, which he helped establish in 2022, began as a collaboration among those working within wastewater management or phosphorus recycling and recovery. Since then, Kabbe has seen its membership expand to around twenty stakeholders across the value chain. This growth has garnered attention from policymakers, who invite the Initiative’s members to join discussions and speak at hearings.

At each opportunity, Kabbe champions three standards for a circular phosphorus economy: a high quality, a market-relevant volume, and a reliable supply.

And after nearly twenty years of tireless work experience in that area, he’s a more passionate advocate than ever.

– I want to make sure that I have tried everything to make the world a better place, or at least not make it worse. That's what keeps me fighting for what’s good, adds Kabbe.